Home » Case Studies »

Our open profile range can lower tare weight in trailers

Australian steel manufacturer, Austube Mills, says its open profile range of angles, channels and flats are lightweight enough to help reduce the overall weight of trailers.

“Over the years, we’ve identified through stringent testing that our profile steel range (coated in DuraGalUltra) – when used in conjunction with our C450Plus hollow section product range – can potentially save up to 15 per cent of the weight of steel sections used to fabricate a trailer,” said Hayden Dagg, Austube Mills Technical Manager, Supply Chain.

According to Austube Mills, there are two reasons why its profiles are suitable for new trailers. One is the actual material. “Our C450Plus square hollow section (SHS) and rectangular (RHS) range is an ideal fit for the design of truck and trailer bodies and tow bars due to its higher strength, which in many applications equates to less steel used and more weight saved,” Dagg said.

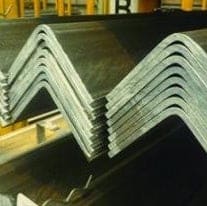

“Both angles (pictured below) and channels (pictured above left) can achieve up to 450 MPa, while flats have a minimum yield strength rating of up to 400 MPa. In fact, in many applications a lighter profile may be substituted for Grade 250/300 hot rolled steel, without making any compromises in compression, tension or bending performance. We are in the business of providing opportunities for significant reductions in material and fabrication costs.”

The second reason is ease of use, as the trailer manufacturer can fit them straight on to the unit. “We’ll make sure we can cover all their customers’ needs, whether it’s SHS, RHS and profiles, or the high-strength C450Plus hollow section range of products,” Dagg said.

“These higher strength products, which retain a high ductility, are definitely amongst our most sourced lines in this sector due to many transport operators wanting lighter weight material for their trailers, in order to maximise payload and lower fuel consumption and costs.”

Article featured in the April 2014 edition of Trailer Magazine.